Concept Generation & selection

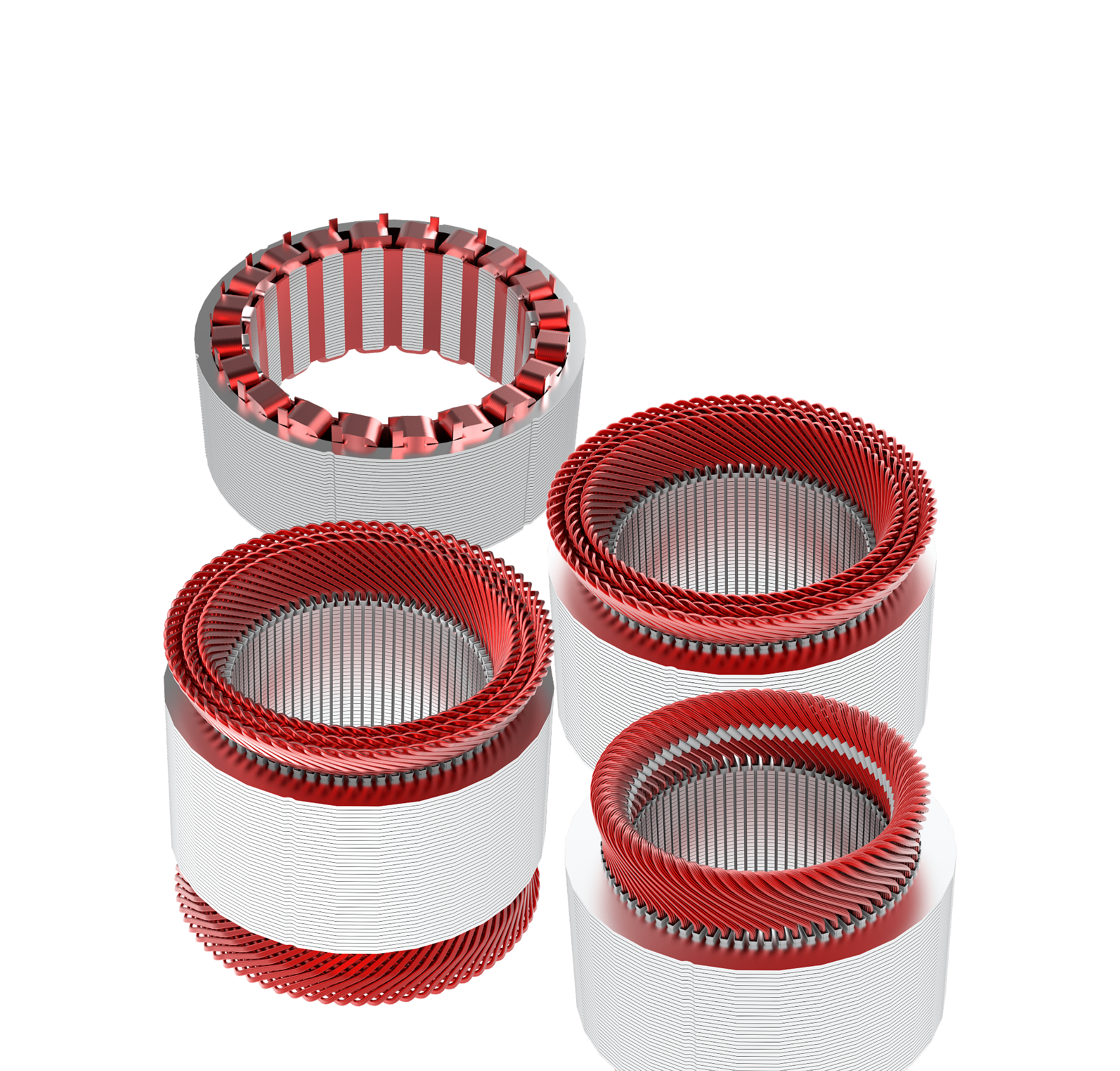

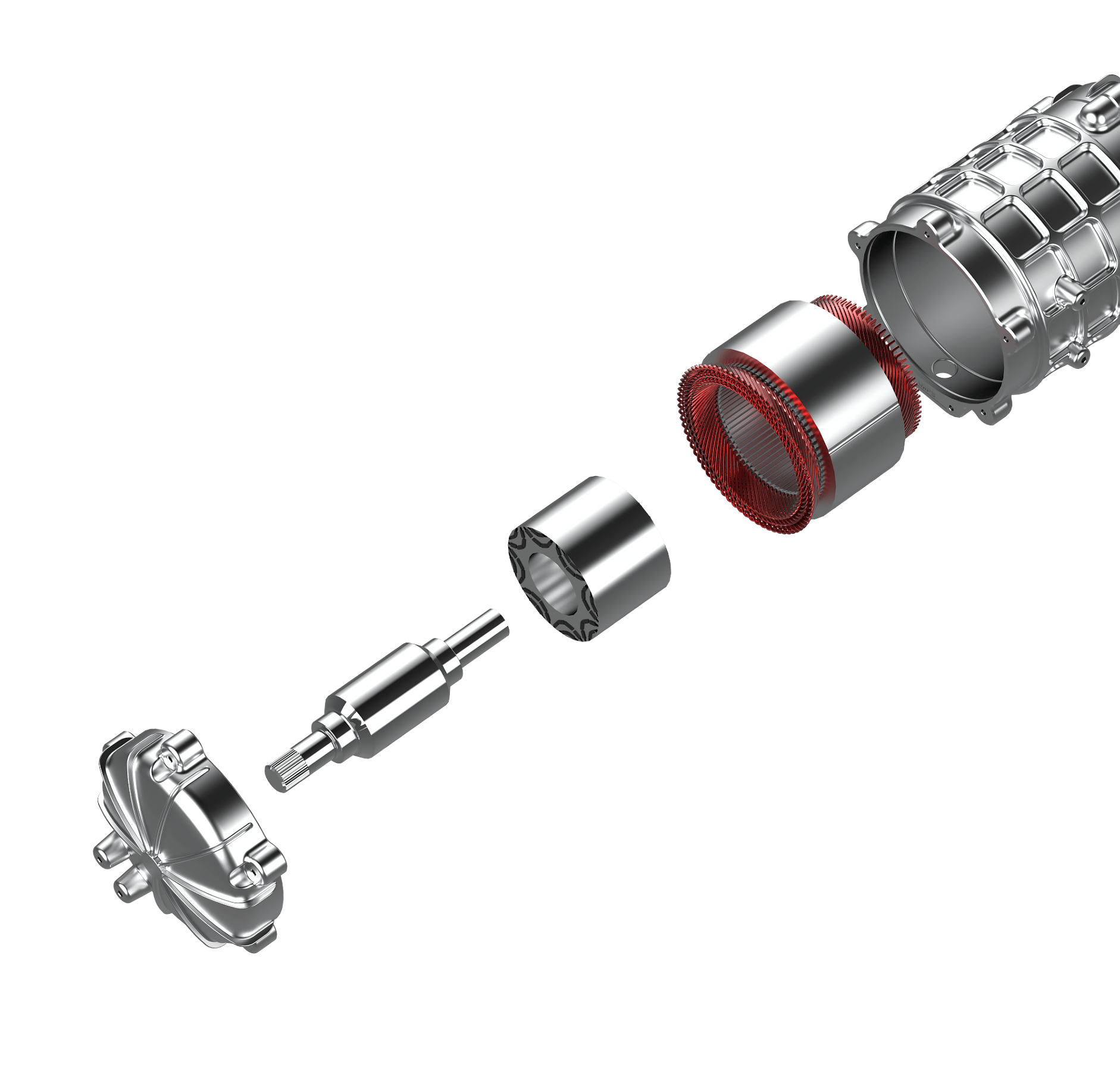

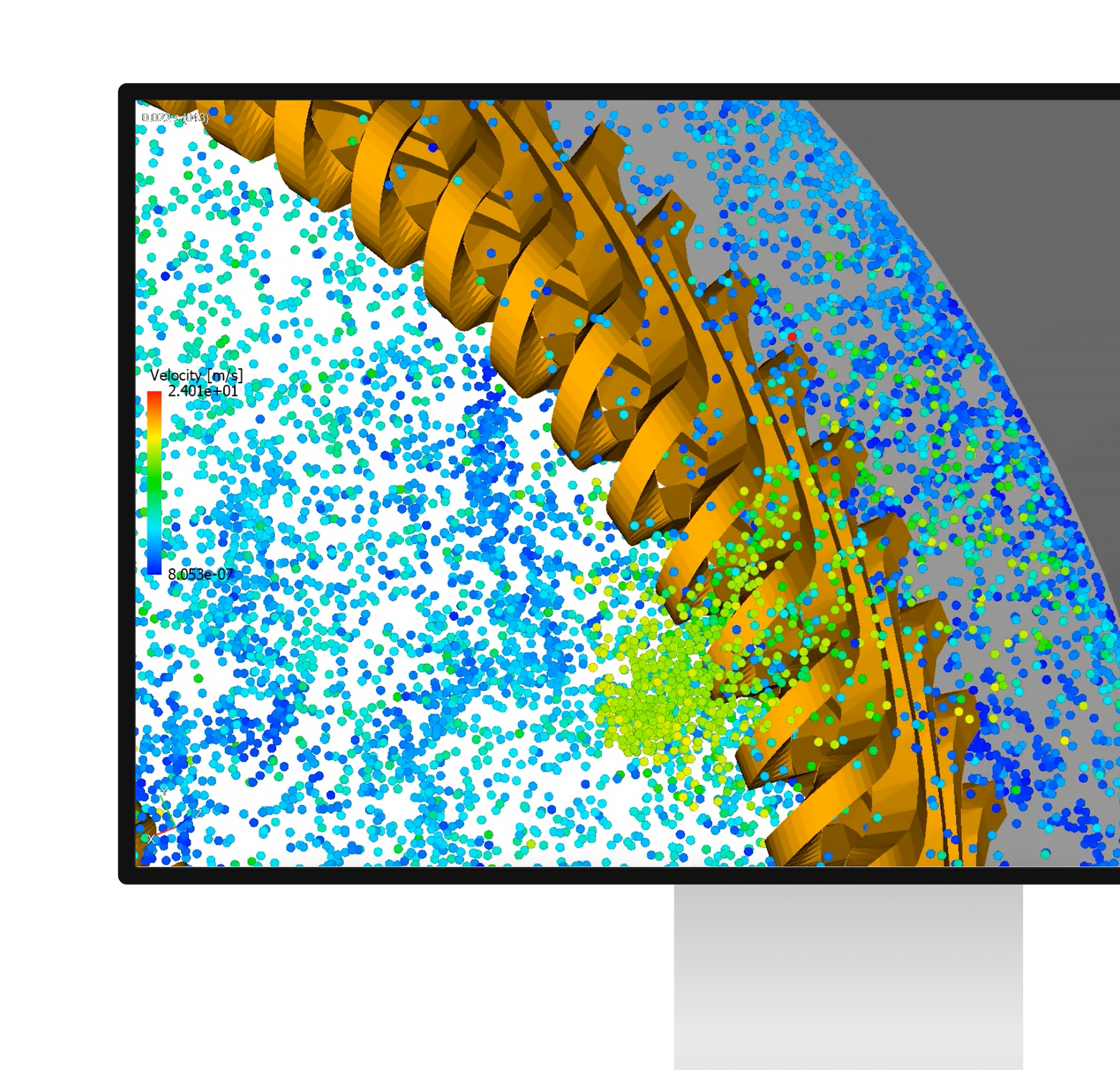

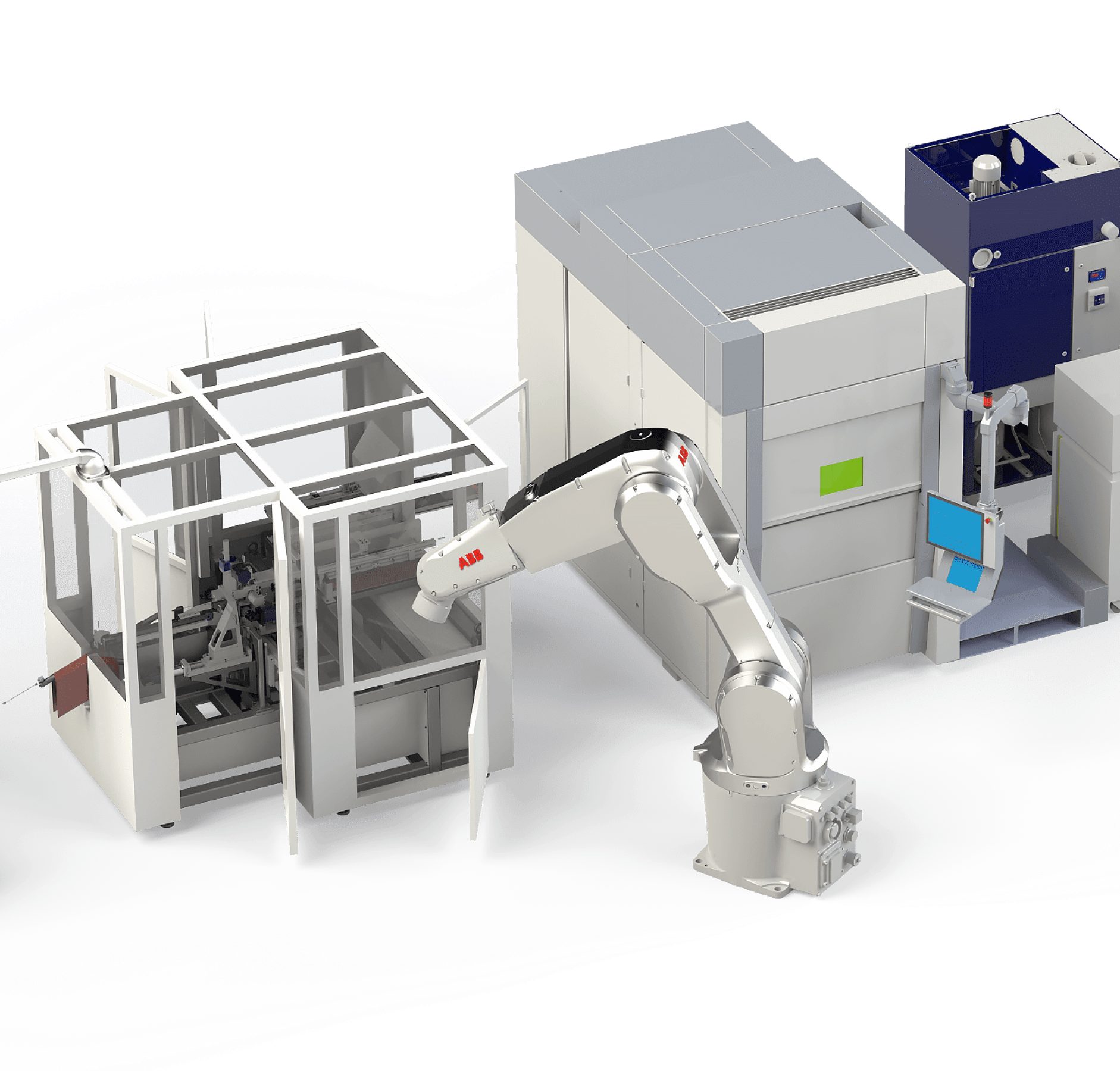

AMPS provides state-of-the-art clean sheet design through to prototyping and testing of electric motor and power electronics modules for the automotive, aerospace, industrial machine and robotic.

AMPS provides state-of-the-art clean sheet design through to prototyping and testing of electric motor and power electronics modules for the automotive, aerospace, industrial machine and robotic. AMPS provides state-of-the-art clean sheet design through to prototyping and testing of electric motor and power electronics modules for the automotive, aerospace, industrial machine and robotic.